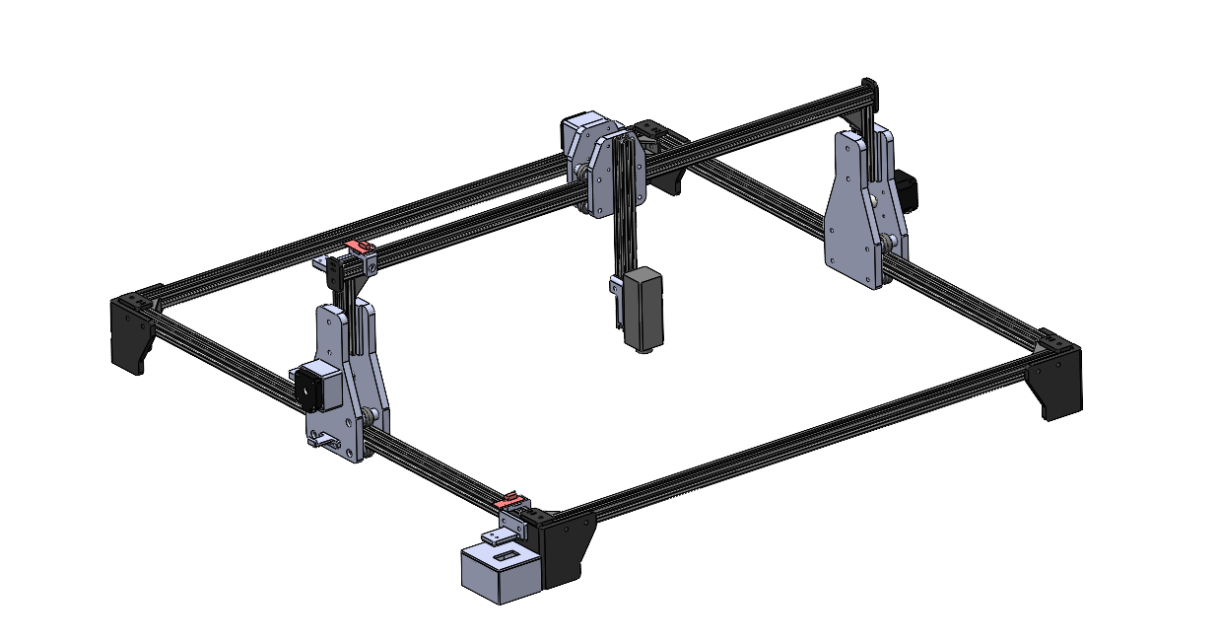

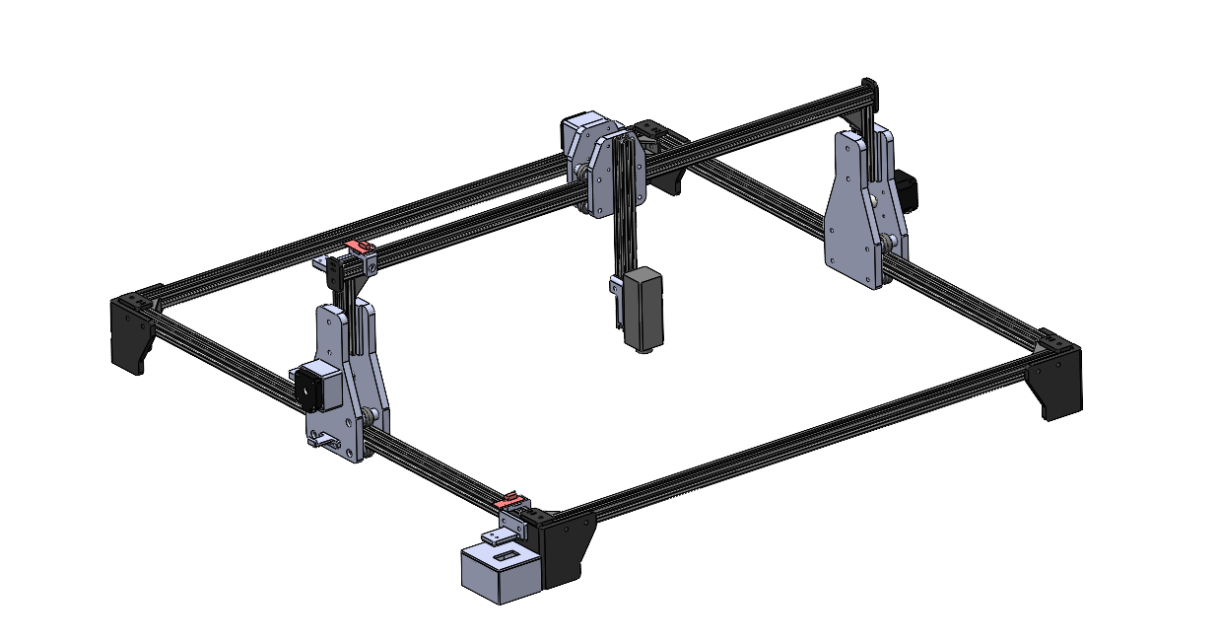

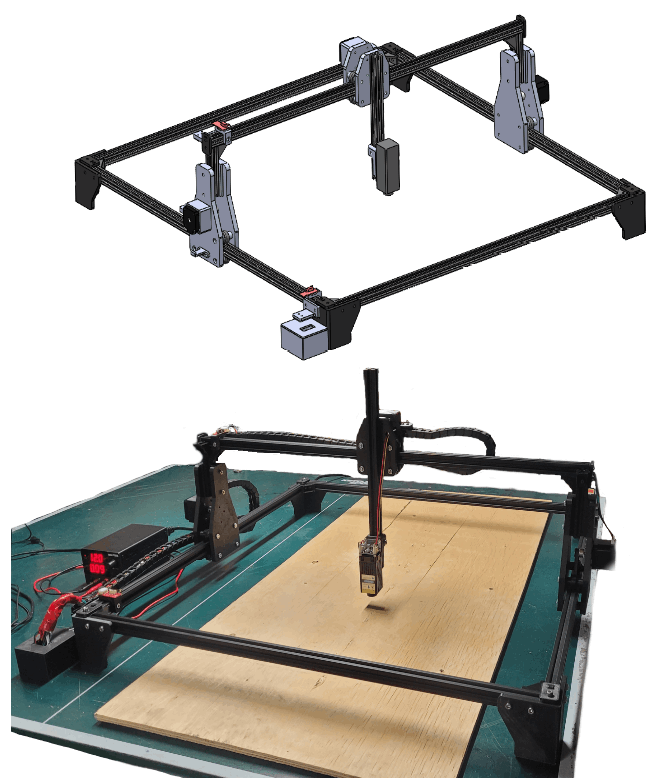

A fixed frame design was constructed using aluminum extrusions to provide a total bed length of 650x650 mm. The Y-axis is driven using two servo motors on opposing sides with a timing belt. The X-axis is driven via a single servo motor with the laser being fixed rigidly to the motor block.

Brackets were designed in SOLIDWORKS using a combination of external CAD files from suppliers for purchased components and then 3D printed in PLA.

In addition, a series of E-Chain links were printed to hold the wires in both the X and Y directions which prevented unessecary wire interference.

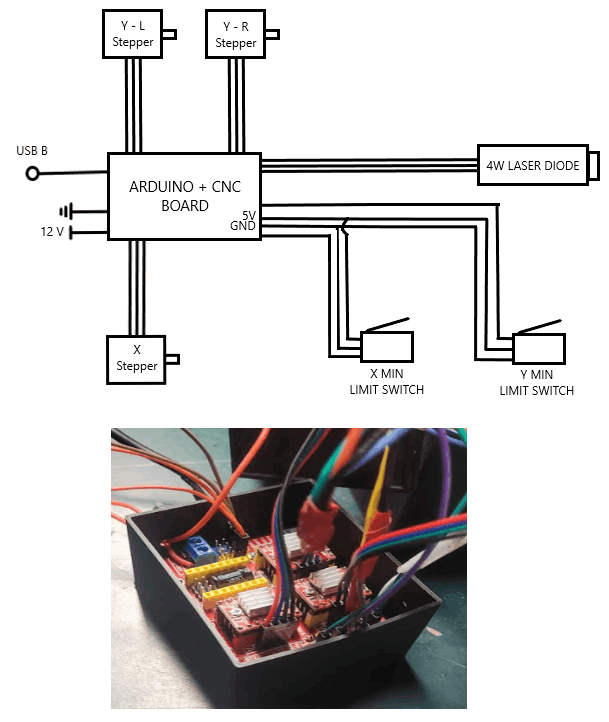

An Arduino Uno was used to drive the system with the addition of an External CNC board with A4988 Stepper Motor Drivers. A 4W 450 nm laser diode was aquired for cheap online which was found to be sufficent for basic engraving. The stepper motors and laser could both be controlled via PWM. In addition, two limit switches were implemented to allow for an auto-homing and calibration of the machine.

It was determined under maximal operating conditions the system would draw a maximum of 3.5 A at 12V. A 30W variable DC power supply was purchased and provided sufficent power.

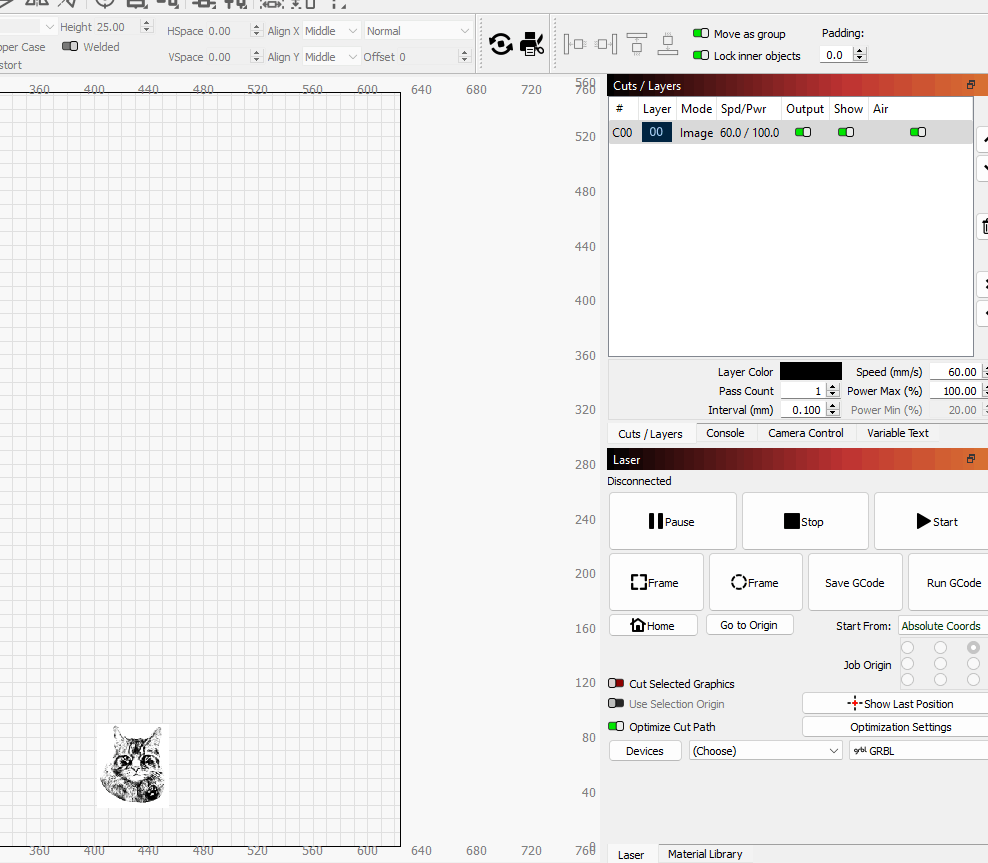

GRBL is an open source CNC driver software that can be used to translate G-CODE into PWM signals. Extensive tuning was requried to ensure operating speeds, offsets, and soft limits. LightBurn was used to generate and flash the system with the generated G-CODE.

A vector image of a cat was used for a test engraving at a speed of 100 mm/s and 250 DPI, which produced the following engraving on the left. The laser can be focused to either work in engraving or cutting mode and works well for both. Microstepping can be implemented on the CNC Arduiono board and may be able to increase resolution during further improvements in the future.