Gallery with Text and Buttons

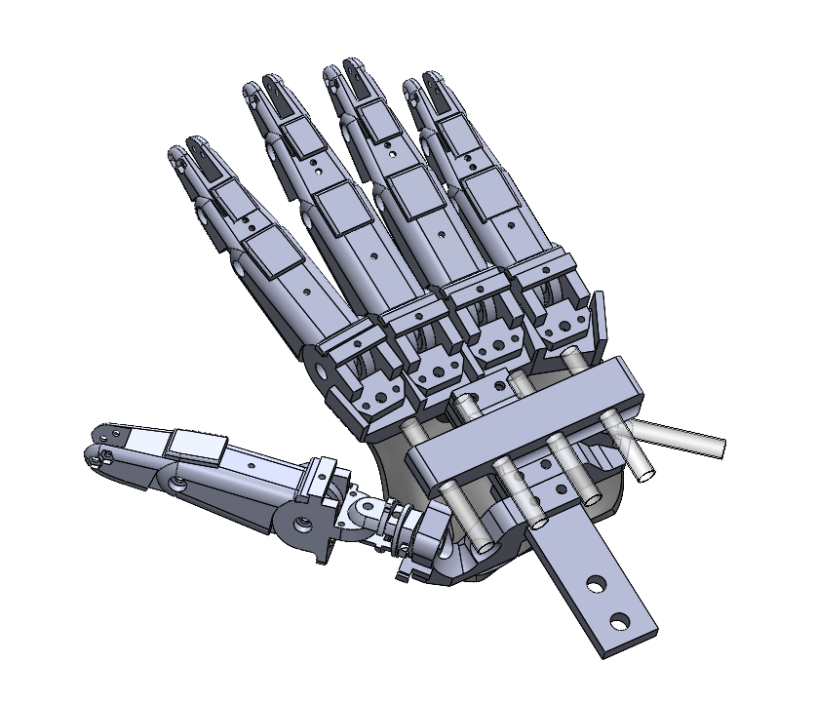

20 DOF Robotic Hand + VR Control

A 20 degree-of-freedom tendon driven robotic hand which is controlled in real time via VR/AR tracking. 3D printed using a combination of PLA and TPU. Joints are actuated via servo motors which are driven by Arduino which is connected to a Python script which connects to a Unity Engine pulling real time hand tracking from a Meta Quest 2. OpenCV and point tracking were used to develop kinematic models and control logic through polynomial interpolation to relate servo angles to finger link rotations.

Skills: SOLIDWORKS, 3D Printing, Arduino, Python, VR, Unity, Servo Motors, OpenCV, numpy

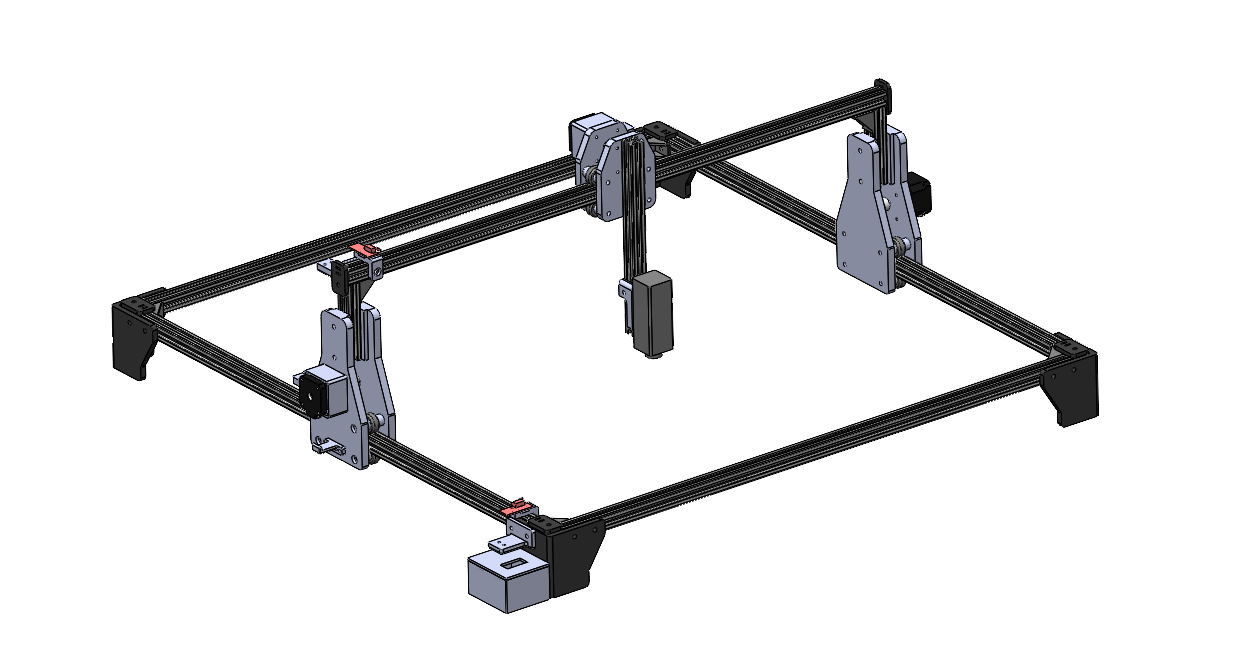

4W Laser Engraver

A 2-axis CNC system for cutting/engraving wood, plastic, and aluminum. Designed from scratch, the majority of components are 3D printed and is driven via an Arduino using GRBL. Capable of 400 DPI precision with a bed-size of 650x650 mm.

Skills: SOLIDWORKS, Arduino, G-CODE, Laser Engraving, Soldering, 3D Printing, Machine Tuning, Stepper Motors, Rapid Prototyping, Component Selection, BOM Development

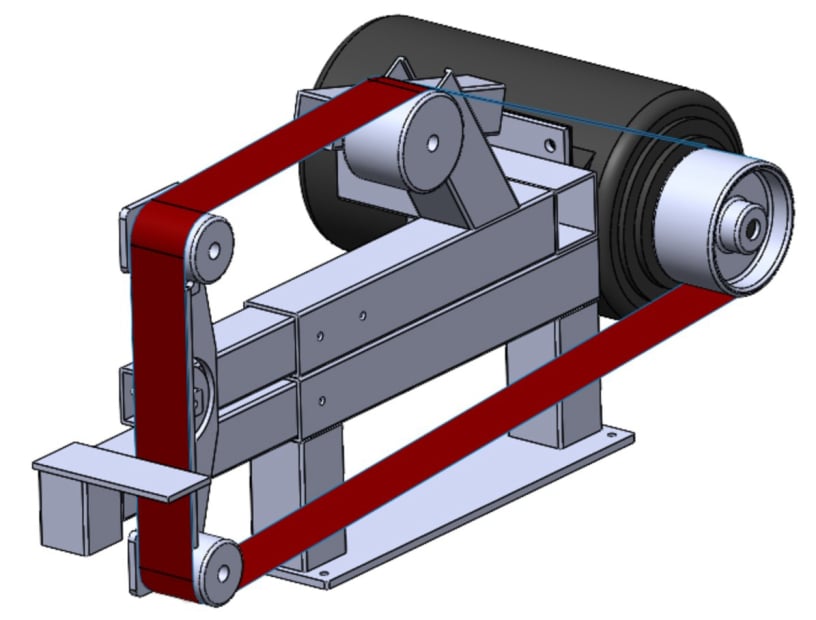

2"x72" 1.5HP Belt Sander

A 1.5 HP 2"x72" belt sander constructed from mild steel. Designed from scratch and welded together using a MIG welder. All components cut and tapped according to CAD specifications by hand. Features a removable grinding platform, adjustable belt tensioner, rotating grind face, and a quick release belt system.

Skills: SOLIDWORKS, MIG Welding, Milling, Grinding, Tappping, Component Selection, BOM Development

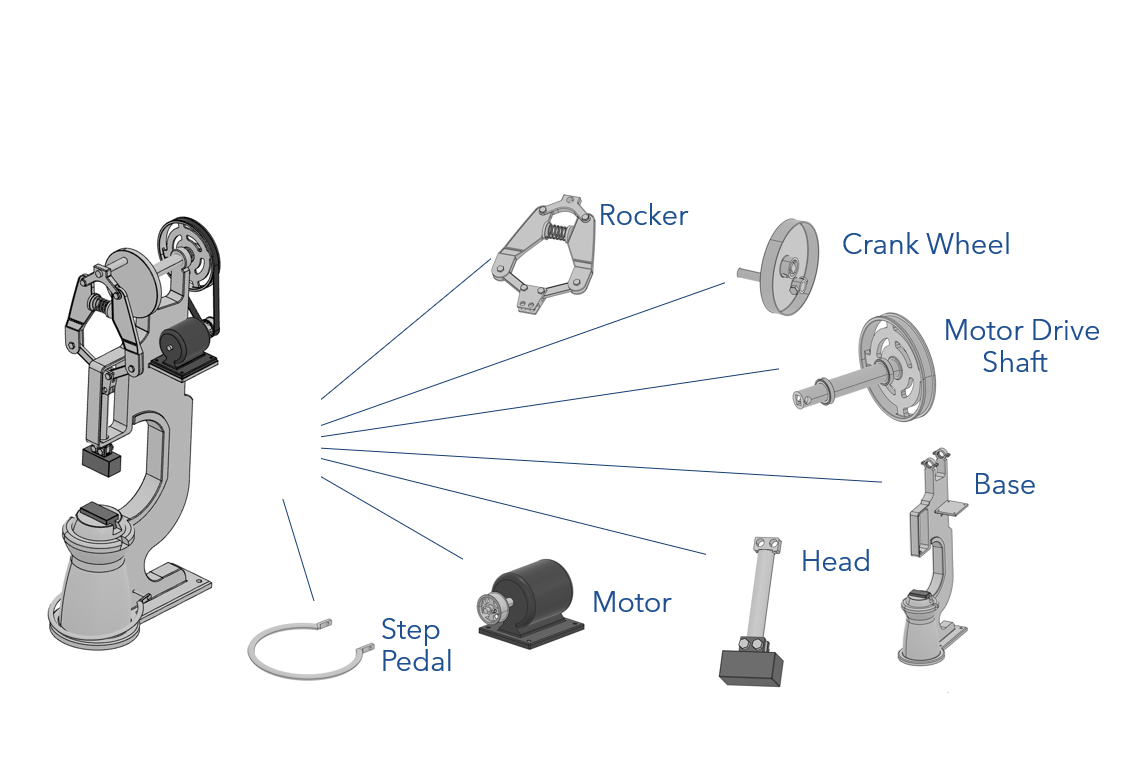

Mechanical Power Hammer System

A power hammer is used in industrial forgining applications to forge hot steel and metals. I modeled, simulated, optimized, and ultimately constructed a physical power hammer prototype for personal forging use. 1-D simulation data was used to select appropriate motor specifications, identify methods of failure and enhance the design.

Skills: CATIA, Mechanism Design, Dymola, Functional & Logical Design, Motor Circuitry & Control Logic, Data Analysis & Optimization

Linear Slider Bearing Tester

Linear Slider Bearings are used to facilitate linear motion without the use a lubricant. Experimental data is needed to accurately predict the lifetime (measured in kilometers travelled) of these bearings for safety critical systems. The slider tester uses a pneumatic cylinder to actuate the tester and is controlled via Arduino. Data captured is then logged in Excel for analysis.

Skills: SOLIDWORKS, C++/Arduino, Pneumatic Design, Vibrational Analysis, Prototype Manufacutring, Data Analysis, BOM Optimization

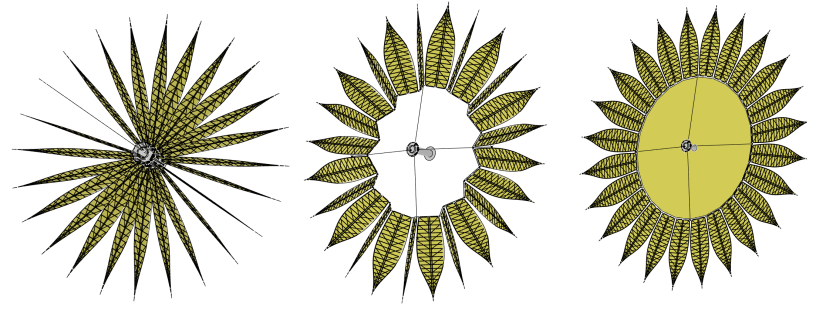

Model NASA Starshade Satellite

The NASA Starshade is a deployable 'origami' satellite that aims to shield a space telescope from the light of surrounding stars to allow for superior photography of exoplanets. A Hoberman frame was developed to study the kinematics of the starshade expansion according to NASA specifications as well as FEA models were prototyped to model the thin-folding of solar "pedals" and an internal mesh.

Skills: CATIA, Mechanism Design, Surface Modeling, Abaqus CAE, Functional & Logical Design

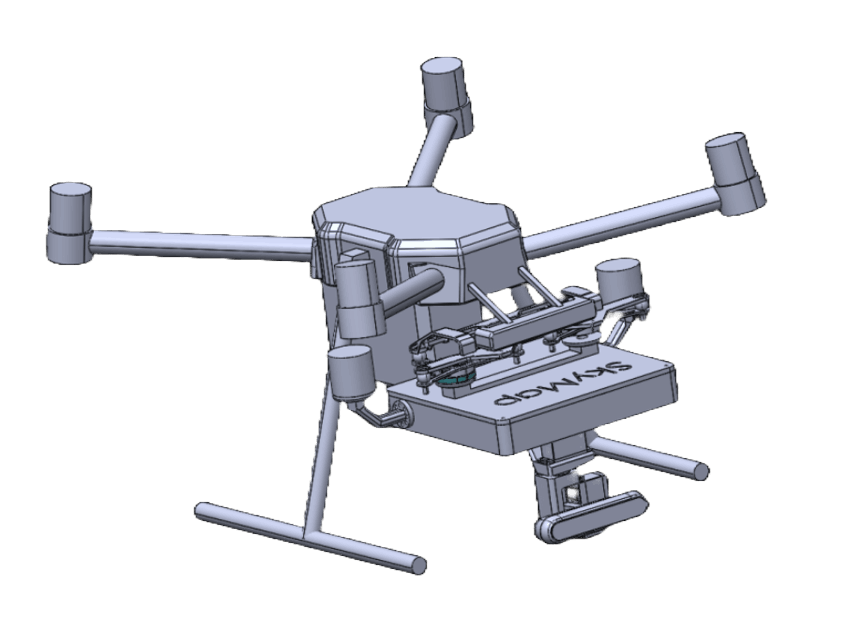

SkyMap - Drone Payload System Gimbal

As part of the Mechatronics Engineer program at the University of Waterloo, all students are required to participate in a Capstone Design Project. SkyMap is a drone based payload system that can be used for creating near real-time scans and 3D renderings of building exteriors. As part of the mechanical development, a gimbal was incorporated as part of the payload to enable a wider scanning radius.

Skills: SOLIDWORKS, 3D Printing, Servo Motors, Compononet Selection, BOM Development, Project Management