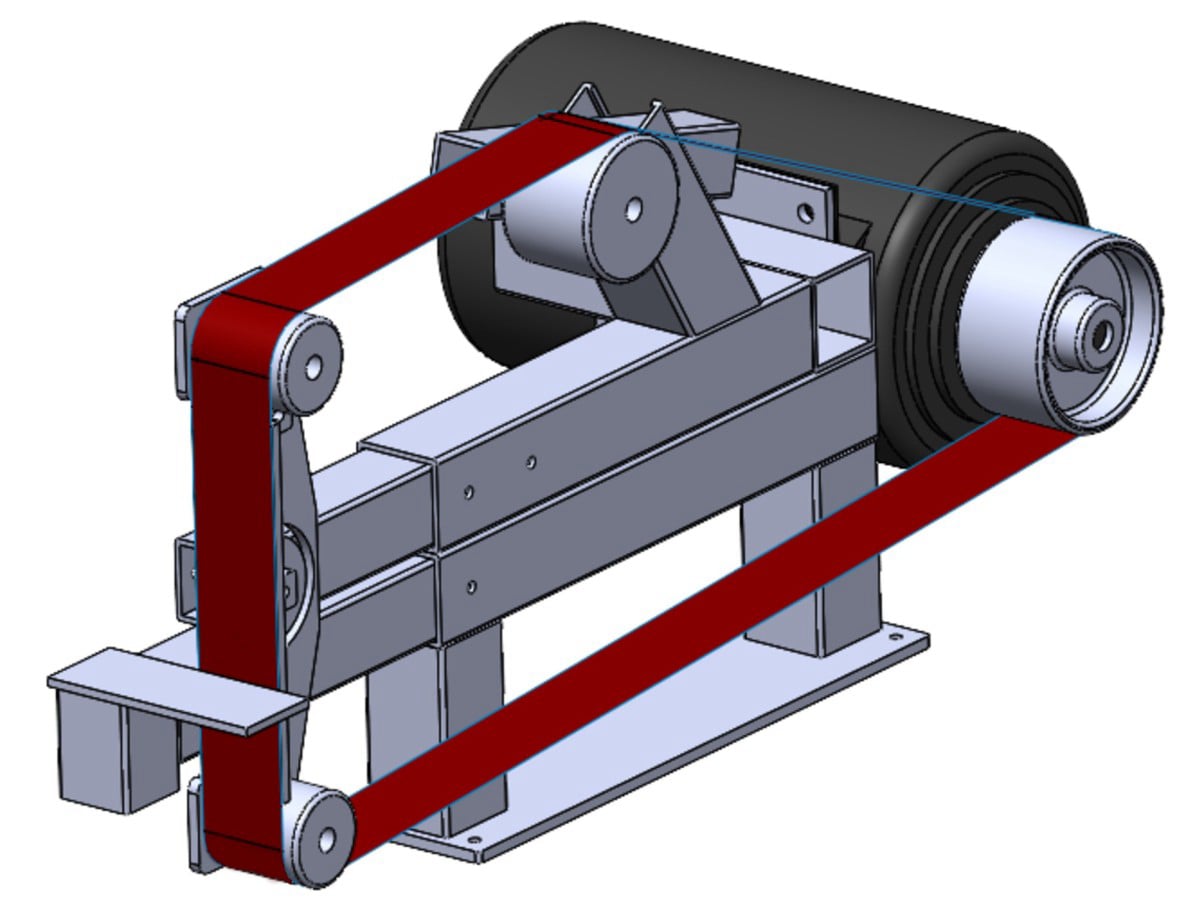

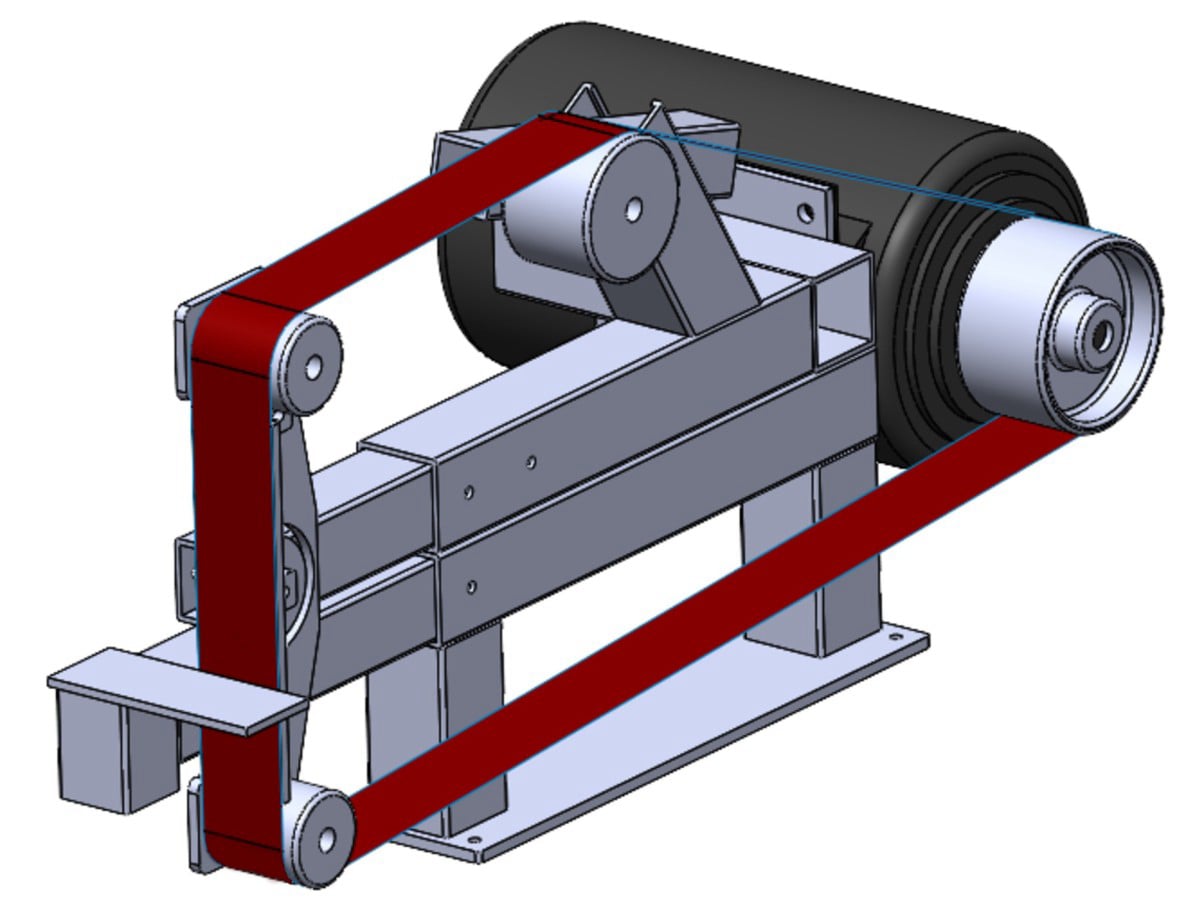

Industrial 2x72" sanders can cost upwards of $1,500 - $2,000, this design, including the motor and belts, cost only $400. The majority of the belt sander was designed using 2x2" mild steel square tubing which would provide sufficient strength to support the motor and grinding forces.

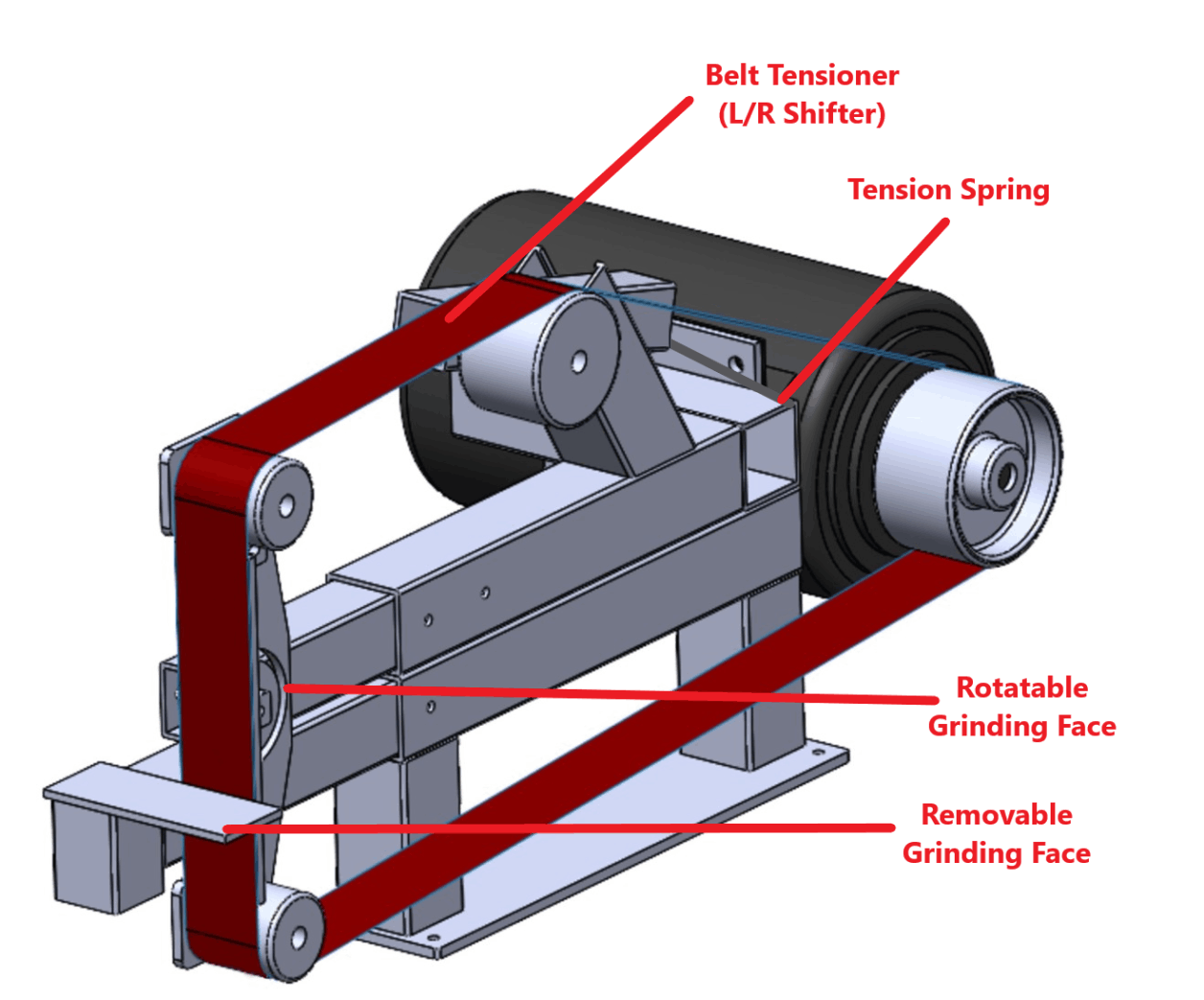

Features a removable grinding platform, adjustable belt tensioner, rotating grind face, and a quick release belt system. A path length function was used to validate all dimensions in CAD would be sufficient to have tension on the grinding belt.

All parts were fabricated by hand based on the CAD sketches prepared. Fasteners were obtained from McMaster Carr and the motor sourced online from an old table saw. The following tools were used in the fabrication process: