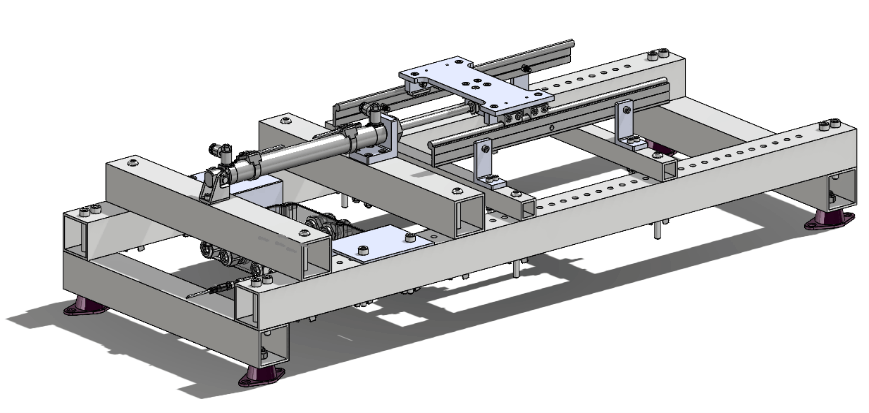

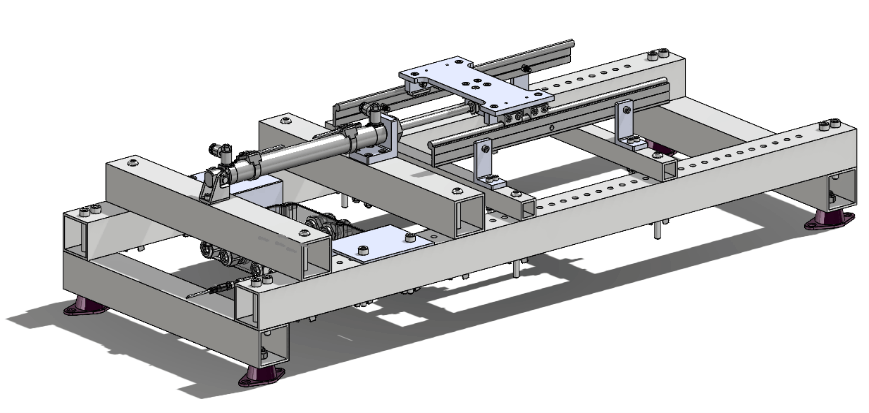

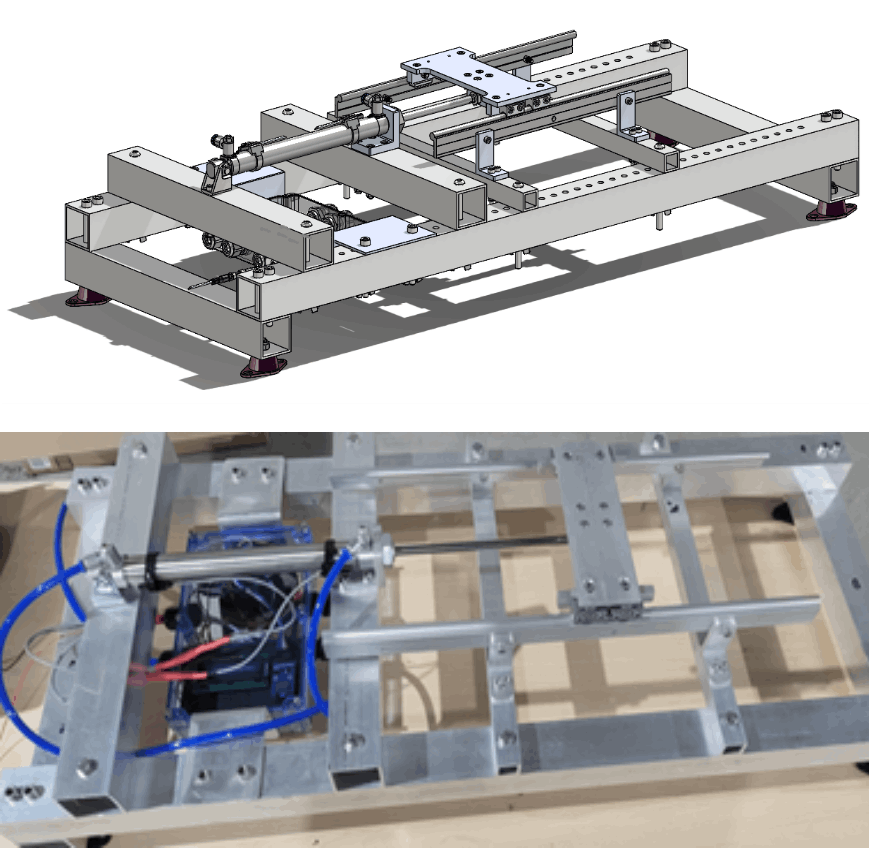

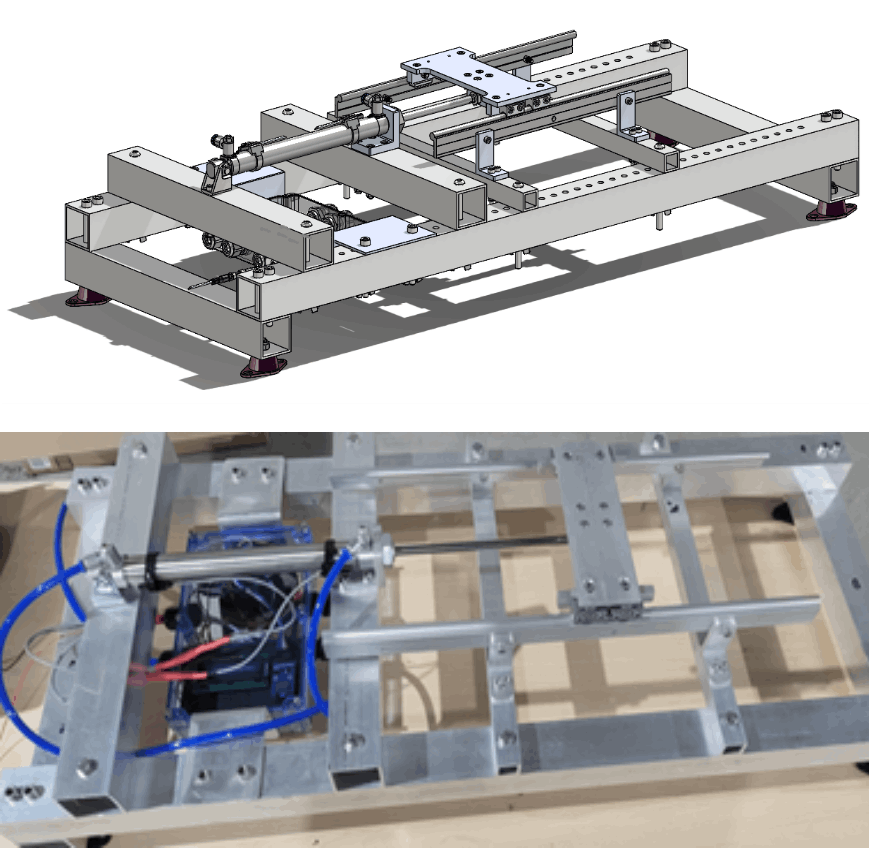

A fixed frame design was selected to minimize vibration impact in the joints of the tester and 6061 aluminum for it's corrosion resistance and weight.

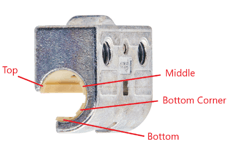

The frame has to parallel rails with a slider that contains four identical slider bearings. This head is repeatedly forced along the rails by a pneumatic cylinder.

The electronics and pneumatic connections are housed within a weather-proof enclosure mounted to the fixture.

Weights can be placed on top of the slider to simulate loading and the slider can be shimmed to model eccentric movement conditions.

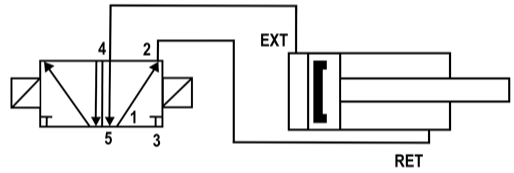

A dual-actuation pneumatic manifold was selected to control the pneumatic supply to the actuation cylinder. The cylinder functions at 100 psi and the manifold is powered via two 12 V DC solenoids which can be invidually triggered.

The manifold is stored within the weather-proof enclosure and has water-tight cord grips for the supply and exhaust lines coming in and out of the box.

An Arduino Uno was used as the main control board and is powered via a L298N dual H-bridge motor copntroller chip which takes in an external 12 V power signal. The Arduino interfaces with two In-Line Auto Switch Proximity sensors to detect the piston head's position within the cylinder and actuate the pneumatic manifold solenoids accordingly.

In addition, time, cycle data, and distance travelled is output to an I2C LCD screen and is additionally logged to a Micro SD card for future analysis.

The Arduino Uno was programmed in C++ where functions where optimized to reduce time and space complexity.

5 different proprietary bearing materials were selected for analysis as well as 13 different environmental scenarios.

Environmental scenarios include:

- Rain/water incursion

- Temperature (heat/cold)

- UV degredation

- Sediment/lubricants

- Localized deformation

- Loading

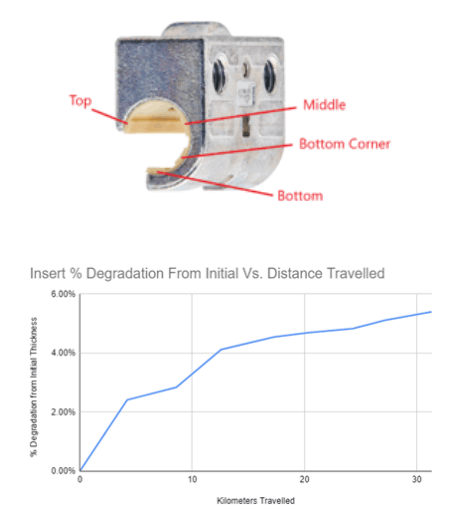

The thickness of each of the bearing pads were measured on the slider bearing after 10,000 cycles and the precent degradation was measured over time to predict the failure time.